At J.P. Hogan, we’ve been at the forefront of pavement grinding and grooving for years. Our expertise in this field runs deep with more than 100 years of combined experience including diamond grinding.

Beneath the hustle and bustle of airport terminals, there’s a critical element that often goes unnoticed: the runways. These stretches of concrete or asphalt play a pivotal role in ensuring the safety and efficiency of air travel. Whether you’re a frequent flyer or a nervous passenger, you’ll appreciate the significance of well-maintained runways.

In this blog post, we’ll dive into the world of airport runway maintenance and unveil the remarkable benefits that diamond grinding brings to the aviation industry. From enhanced safety to cost-effective solutions, J.P. Hogan is your trusted partner for peak condition airport runways.

Fasten your seatbelts, because we’re about to take off on a journey through the advantages of diamond grinding for airports.

What is Diamond Grinding?

When people hear the word diamond, they often think of jewelry, but that’s not the gemstones only use, let alone its most innovative. Diamond grinding is a specialized concrete maintenance technique that works wonders on airport runways. But what exactly is it, and how does it breathe new life into worn-out surfaces?

Essentially, diamond grinding involves the use of cutting-edge machinery equipped with diamond-tipped blades. These industrial-grade diamonds are incredibly hard, making them perfect for the task at hand. As the equipment moves across the runway’s surface, these diamond blades meticulously grind away imperfections, leaving behind a smooth surface.

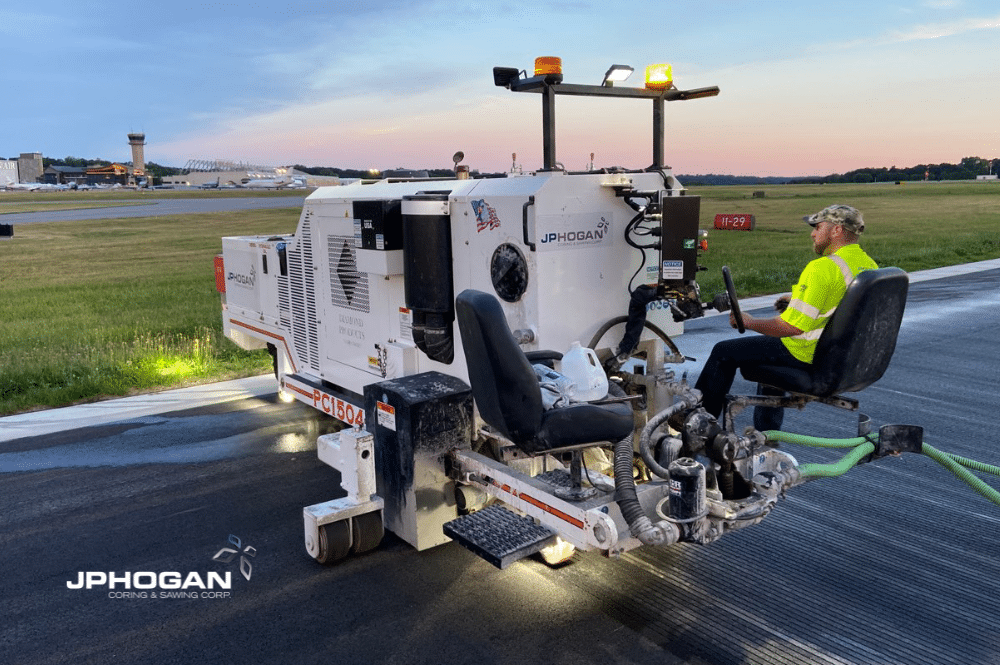

The machinery behind the magic: An overview of equipment and technology

To achieve the precision and excellence that J.P. Hogan is known for, we rely on state-of-the-art equipment and cutting-edge technology. Our Tier 4 grooving and grinding machine is a prime example of innovation in action. This marvel of engineering ensures we deliver exceptional results not just on airport runways but also on bridge decks, parking decks, and various other slab applications.

Diamonds in the rough: Unveiling the role of diamond blades

Now, let’s talk about the real stars of the show: diamond blades. These remarkable tools are at the heart of the diamond grinding process. With their exceptional hardness and durability, diamond blades have the power to remove irregularities and imperfections from runway surfaces with unparalleled precision.

As they cut through the pavement, these diamond-tipped blades create a profile that meets the highest industry standards. The result? A smooth and flawless runway surface that enhances safety, extends longevity, and reduces maintenance costs.

When it comes to airport runway maintenance, it’s the combination of expertise, technology, and diamond blades that allows us at J.P. Hogan to deliver exceptional results, one runway at a time.

Safety Enhancements

Traction is one of the most important features of airport runways because the safety of passengers, crew, and aircraft depends on it. Diamond grinding, our trusted method, works to improve traction and keep the plane on the runway – not the grass. Here’s how:

Reduced Risk of Hydroplaning: Imagine a wet, rainy day at the airport. Aircraft land and the runway glistens with rainwater. It’s at moments like these when the difference made by diamond grinding becomes clear. By creating a meticulously grooved surface, we significantly reduce the risk of hydroplaning. This means aircraft can maintain solid ground contact, even on slippery runways, ensuring safer landings and takeoffs.

Enhanced Control During Landing and Takeoff: Air travel is all about precision, and every inch counts when it comes to controlling an aircraft. Diamond grinding plays a pivotal role in enhancing control, allowing for smoother and safer landings and takeoffs, even in adverse weather conditions.

Fewer Accidents, More Peace of Mind

One of the most significant benefits of diamond grinding is the reduction in accidents and incidents on airport runways. The improved surface conditions created by this technique drastically minimize the chances of mishaps.

Elevating Airport Safety and Air Travel

At J.P. Hogan, we’re not just passionate about the quality of our work; we’re dedicated to the safety of passengers and everyone involved in air travel. The impact of diamond grinding on overall airport safety cannot be overstated. It transforms runways into secure, high-traction surfaces, fostering a safer environment for all.

So, whether you’re a passenger, a pilot, or an aviation enthusiast, you can rest assured that diamond grinding is a key player in enhancing airport safety and ensuring smoother, safer journeys through the skies.

Economic Benefits of Diamond Grinding

Runway surfaces endure relentless wear and tear from the constant planes, vehicles, and luggage carts that use them. But with diamond grinding, we’re not just restoring runways; we’re extending their lifespan. By addressing imperfections and creating a smoother surface, we reduce the need for frequent maintenance. This translates into substantial cost savings for airports in the long run, sparing them from the financial burden of constant repairs and renovations.

Plus, runway repairs are costly and disruptive to airport operations. Diamond grinding acts as a shield, warding off the need for frequent repairs. Runways can withstand the test of time, ensuring smoother and more efficient air travel without the constant interruption of construction work.

The benefits of diamond grinding aren’t confined to airport authorities alone. Airlines, too, experience a substantial impact on their bottom line because it increases airport efficiency leading to fewer flight delays.

The economic benefits of diamond grinding extend far and wide, benefiting both airports and airlines. It’s an investment that pays dividends, fostering smoother operations, lower costs, and ultimately, a more enjoyable flying experience for all.

Environmental Considerations

Today, environmental stewardship is a growing concern and every industry must take steps towards a more sustainable future. The aviation industry, with its significant impact on the environment, is no exception.

At J.P. Hogan, we understand the importance of balancing the demands of efficient airport operations with our responsibility to minimize environmental impact.

From reducing noise pollution during landings and takeoffs to minimizing dust and debris, we’re committed to sustainable practices that benefit both the aviation industry and the planet we all share.

Quieting the Skies: Reduced Noise Pollution During Landings and Takeoffs

Airports can be bustling and noisy places, especially during landings and takeoffs. However, diamond grinding plays a role in reducing this noise pollution. The smoother surface created through this method allows aircraft to make contact with the runway more gently, resulting in quieter operations. This not only benefits those living near airports but also contributes to a more peaceful travel experience for passengers and crew.

Clearing the Air: Minimized Dust and Debris

Construction and maintenance activities on runways can stir up significant amounts of dust and debris, impacting both the environment and air quality. Diamond grinding, with its precise and controlled approach, minimizes the release of dust and debris resulting in cleaner air and less environmental disturbance around the airport.

Sustainable Skies: Environmentally Responsible Diamond Grinding

At J.P. Hogan, we take sustainability seriously. We’re committed to environmentally responsible practices in diamond grinding. Our methods are designed to minimize environmental impact while delivering exceptional results.

By choosing diamond grinding for runway maintenance, airports align themselves with sustainable practices that benefit not only the environment but also the communities they serve.

Diamond grinding has emerged as a responsible choice for airport runway maintenance. It’s a step towards quieter skies, cleaner air, and a more sustainable aviation industry.

Comparing Diamond Grinding to Alternative Methods

When it comes to maintaining airport runways, there’s more than one way to keep them in tip-top shape. While diamond grinding is our specialty and a proven method, it’s worth taking a moment to explore the alternatives that exist in the world of runway maintenance.

Why Diamond Grinding Soars Above the Rest: Advantages Galore

Among the various approaches available, diamond grinding stands tall, and for good reason. It offers a slew of advantages that set it apart as the premier choice for airport runway maintenance.

First and foremost, diamond grinding is incredibly precise, leaving behind an impeccably smooth surface that other methods struggle to achieve. This precision translates into enhanced safety, as the improved runway surface provides better traction and control during takeoffs and landings.

What truly sets diamond grinding apart though, is its longevity. Unlike some alternatives that require frequent and costly repairs, diamond grinding extends the life of runway surfaces. This not only saves airports substantial sums in long-term maintenance costs but also reduces the need for disruptive runway repairs that can wreak havoc on flight schedules.Diamond grinding minimizes operational downtime, ensuring that runways are ready for action with minimal interruptions.

So, while alternative methods may have their merits, none quite match the precision, longevity, and efficiency that diamond grinding brings to the table. It’s a clear choice for airports that prioritize safety, cost-effectiveness, and streamlined operations.

The Role of J.P. Hogan in Airport Diamond Grinding

At J.P. Hogan, we don’t just offer airport diamond grinding; we bring decades of expertise to the runway. With a team of highly skilled professionals and cutting-edge equipment, we’ve become synonymous with precision and quality in airport runway maintenance.

Our experience spans a wide range of projects, from bustling international airports to regional hubs. Whether it’s a complex runway renovation or routine maintenance, our capabilities are unmatched. We take pride in being the go-to choice for airports seeking top-notch diamond grinding services.

Smooth Landings: The Process of Working with J.P. Hogan for Airport Diamond Grinding

Working with J.P. Hogan is a seamless experience from start to finish. It begins with a comprehensive assessment of your runway’s condition and specific requirements. Our team of experts collaborates closely with airport authorities to create a customized plan that addresses your unique needs.

Once the plan is in place, our state-of-the-art equipment and skilled operators take flight. We meticulously execute the diamond grinding process, adhering to the highest industry standards. The result? A flawlessly smooth runway surface that elevates safety and efficiency.

But our commitment doesn’t end there. We understand the importance of minimizing operational disruptions, so we work efficiently to ensure that your runway is back in action as soon as possible. It’s this dedication to quality and efficiency that sets J.P. Hogan apart as your trusted partner in airport diamond grinding.

Stories of Excellence: Success Stories and Projects Completed by J.P. Hogan

Our track record speaks volumes about our capabilities. Over the years, we’ve had the privilege of working on a multitude of projects that have left a lasting impact on airports and the aviation industry. From enhancing safety to reducing maintenance costs, our success stories are a testament to our commitment to excellence.

These stories aren’t just about runways; they’re about the people we serve. They’re about the passengers who experience smoother landings, the airlines that benefit from reduced operational costs, and the airport authorities who trust us with their runways.

In the world of airport diamond grinding, J.P. Hogan isn’t just a service provider; we’re a partner in progress, dedicated to shaping the future of aviation, one perfectly paved runway at a time.

A Runway of Benefits: Summarizing the Key Advantages of Diamond Grinding for Runways

As we conclude our journey through the world of airport diamond grinding, let’s take a moment to recap the benefits that this method brings to the aviation industry.

Diamond grinding, with its precision and longevity, stands as a beacon of safety and efficiency for airport runways. It reduces the risk of hydroplaning, enhances control during landings and takeoffs, and minimizes accidents due to improved surface conditions. This translates into safer skies for all.

Economically, diamond grinding extends the lifespan of runway surfaces, resulting in substantial cost savings and reduced operational expenses for airlines. It fuels airport efficiency, reducing flight delays and keeping air travel on track.

Paving the Way for Safe and Efficient Air Travel

The importance of maintaining safe and efficient runways cannot be overstated. These critical components of the aviation infrastructure serve as the lifelines of air travel, connecting passengers to their destinations safely and swiftly. Diamond grinding is more than a maintenance method; it’s a commitment to upholding the highest standards of safety and operational excellence in the aviation industry.

Choose Excellence: Consider Diamond Grinding for Your Pavement Maintenance Needs

To our fellow aviation industry stakeholders, we extend a simple yet powerful message: Consider diamond grinding for your pavement maintenance needs. This method isn’t just a choice; it’s a decision to prioritize safety, efficiency, and sustainability.

Our Promise: Quality and Safety in Airport Services

At J.P. Hogan, our commitment to quality and safety in airport services is unwavering. We understand the critical role that well-maintained runways play in air travel, and we take that responsibility to heart. From precision diamond grinding to environmentally conscious practices, we’re dedicated to shaping a future where airports are safer, more efficient, and kinder to the environment.